Additive Manufacturing of Titanium Aircraft Parts

source:Photonics

release:Nick

keywords: Additive Manufacturing; 3D laser printing

Time:2017-11-06

TOMSK, Russia, Nov. 3, 2017 — An additive manufacturing technology that uses direct metal laser sintering enables the printing of titanium aircraft parts with a modified surface layer.

Physicists from Tomsk Polytechnic University (TPU) are currently working to create hydrogen-resistant products out of titanium alloys. The production of metal products via additive manufacturing ensures less material consumption as well as possibilities to develop complex geometric products. The Russian Science Foundation has given TPU a three-year grant for the creation of hydrogen-resistant products from titanium alloys Ti-6Al-4V, Ti-6.5Al-3.5Mo-1.5Zr-0.3Si.

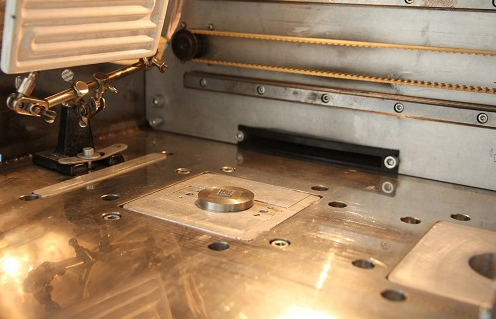

A 3D-printed titanium sample. Courtesy of Tomsk Polytechnic University.

A 3D-printed titanium sample. Courtesy of Tomsk Polytechnic University.

Titanium products are widely used in aircraft construction due to their strength, and account for 15 to 20 percent of a modern civil aircraft. Today, these parts are produced with traditional foundry though.

"In Russia it is a fairly new technology. To introduce it, special 3D-printing equipment and powder production installation should be developed. Thus, there is a great scope for research,” said Natalia Pushilina, associate professor at TPU’s Department of General Physics. “This equipment is increasingly in high demand as evidenced by the great number of scientific publications devoted to additive manufacturing technology in the field of metal processing. Over the past few years, their number has significantly increased in leading scientific publication databases, which signifies a great interest in the international community.'

Pushilina and her team plan to print aircraft parts out of BT6 and BT9 titanium alloys. BT6 is a widespread material being produced in Russia, while BT9 will be obtained by TPU out of crystalline titanium.

“For the research, we chose these two materials, as they have been applied in aircraft construction due to their properties,” said Pushilina. “BT6 is used to manufacture turbine parts subject to high temperatures, corrosive media and saturation with atmospheric hydrogen during operation.”

According to the researchers, 3D-printing with titanium alloys differs from traditional processes in that it relies on laser-based additive manufacturing technology that makes it possible to make parts of any configuration. It also uses much less materials.

“With 3D technology you can print any part. This goes beyond mass production supported by plants that daily cast a great deal of products,” said engineer Viktor Kudiyarov. “Our goal is to develop a technology for printing individual complex parts out of titanium.”

TPU scientists are determined to reveal patterns between various print parameters and characteristics of manufactured items. So far, they have identified over 10 parameters. By varying them, it is possible to create products with different specified properties and products with gradient surface layers.

Currently, such modification of products requires an additional production process. First, a homogeneous part is made, then an additional coating is applied. The technology developed by TPU scientists combines the two processes. Products are printed immediately with a modified layer.

TPU physicists are committed to showing the advantages of titanium parts produced by using advanced additive technology.

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms?

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms? DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey

DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave

Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80%

Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80% Global LiDAR Giants Engage in Escalating Patent Wars

Global LiDAR Giants Engage in Escalating Patent Wars

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer

Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy

Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>

Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>